1、Compostable Polyesters A200

A200 is a compostable polyester produced through polycondensation reaction, consisting of 1,4-utanediol and succinate acid. When metabolized in the soil or compost under standard conditions, A200 will be biodegraded into small monomers. These small monomers will be taken by microorganisms, and eventually biodegraded into carbon dioxide and water. A200 complys with OM6 in EU 10-2011,

which is especially suitable for food contact materials. Alike LDPE, A200 is soft and flexible semi-crystalline polyester with excellent properties suitable for injection molding articles and extrusion products for general purpose.

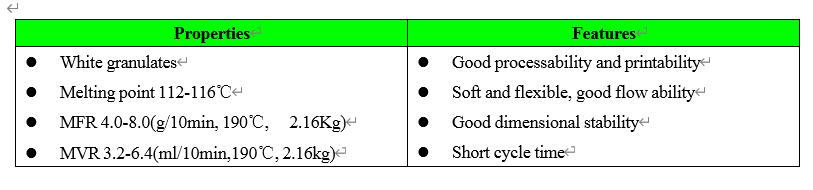

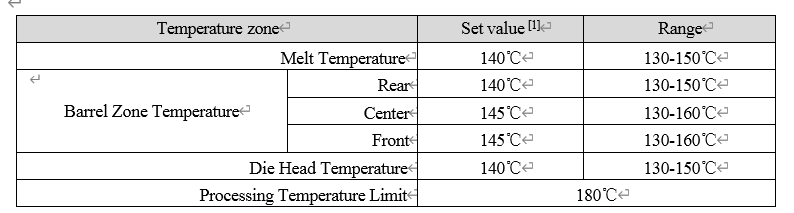

Resin Property

A200 has similar mechanical and process properties to LDPE. The listed values are measured by test specification and used for referential purpose only.

Processing Information

A200 has good processing stability. It can be used alone or blended with other material through conventional injection process. Well packaged products can be used directly. If package is damaged before use, the product should be dried prior to processing. Moisture levels above 800ppm may impair injection operation. Effective drying takes place at 80°C for 4 hours. The dried product should keep away from moisture.

Quality Control:

A200 is produced through an optimized continuous polycondensation process, with online melt viscosity and MFR control.

Packaging and Storage:

A200 is supplied in 800Kg Octobin. Transportation and storage temperature should not exceed 70 ℃ . Well packaged. Product should be stored under 23 ℃ and used up within 12 months. Once the package opened, the product should be used as soon as possible.

2、ECOPOND® Compostable Polyesters A400

A400 is one compostable random copolymer produced through a polycondensation reaction, consisting of a copolyester of 1, 4-butanediol, adipic acid and terephthalate acid. When metabolized in the soil or compost under standard conditions, A400 will biodegrade into small monomers. These small monomers will be taken by microorganisms, and eventually biodegrade into carbon dioxide and water. The compostability of A400 fulfills the requirements of DIN V 54900-1, EN 13432, ASTM D 6400 standard, and the material meets the U.S. FDA food safety standard. The high molecular weight of A400 makes it possible for blown or cast film, alone or blended with other materials. A400 is a compostable alternative to LDPE, with many similar properties including flexibility and resilience. Particular applications include cling wrap for food packaging, compostable plastic bags for gardening, agricultural usage, and as water resistant coatings for other materials, such as in paper cups.

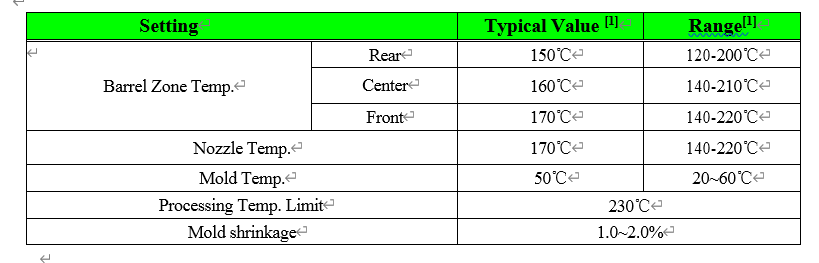

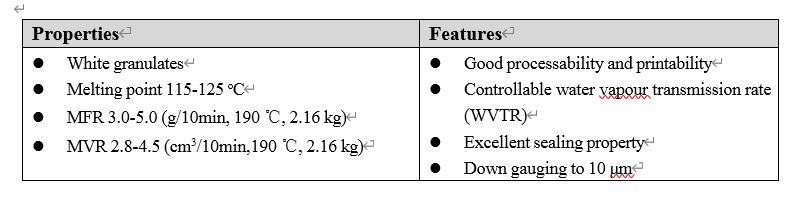

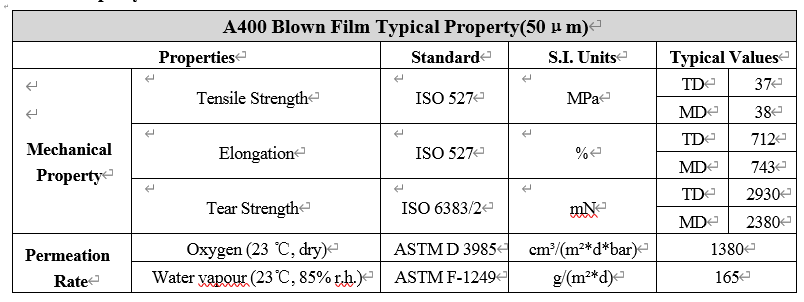

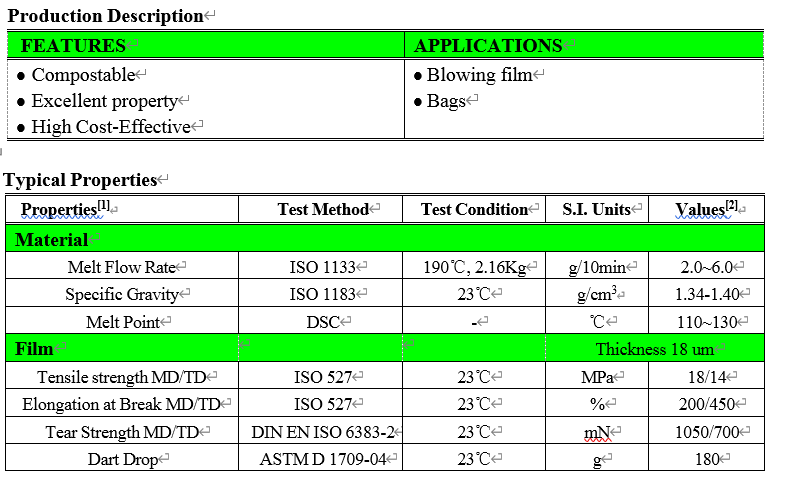

Resin Property

A400 has similar mechanical and processing properties to LDPE. The listed values are measured by test specification and used for referential purpose only.

Film Property

Processing Information

A400 has good processing stability. It can be used alone or blended with other material through

conventional blowing or casting process. Well packaged products can be used directly. If package had been damaged before use, the product should be dried prior to processing. When the moisture content exceeds 500 ppm, film-blowing will be affected. Effective drying takes place at 80 oC for 4 hours. The dried product should keep away from moisture.

Quality Control

A400 is produced through an optimized continuous polycondensation process, with online melt viscosity and MVR control.

Packaging and Storage

A400 is supplied in 800 kg/bigbag or 1200 kg/bigbag. Temperatures during transportation and storage may not exceed 60 oC at any time. Storage time in an unopened bag may not surpass 12 month at room temperature (23 oC). Use as soon as possible if the package had been broken.

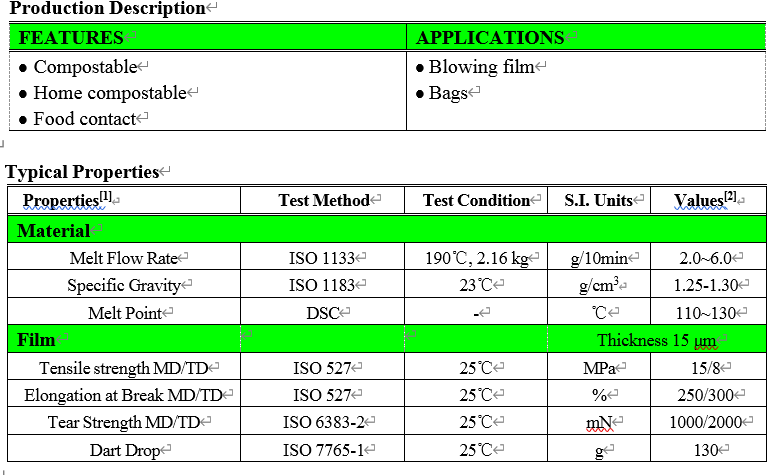

3、ECOPOND® Compostable Polyesters C200 S20

Quality Control

The melt flow rate, MFR, at 190℃, 2.16 kg, according to ISO 1133 has been defined as specified parameter for quality control. A certificate can be provided with each lot number upon request. In order to obtain a high accuracy for the MFR measurement, the granules should be dried for 4 hours at 80℃.Other data given in our literature are typical values, which are not part of our product specification

Storage

Temperatures during transportation and storage may not exceed 70℃ at any time. Storage time in an unopened bag may not surpass 12 month at room temperature (23℃).

Well packaged products can be used directly. If package is damaged before use, the product should be dried prior to processing. Moisture levels above 1000 ppm may impair film-blowing operation. Effective drying takes place at 80°C for 4 hours. The dried product should keep away from moisture. The data sheet is just for reference. In actual process, the parameter should be adjusted.

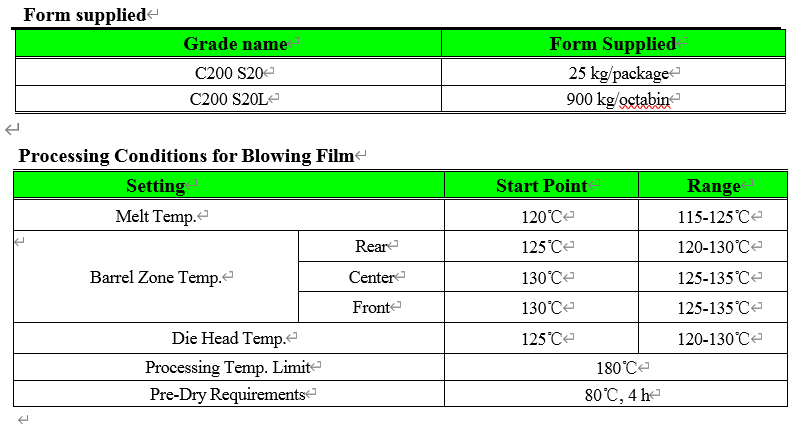

4、ECOPOND® Compostable Polyesters D200 A10

Quality Control

The melt flow rate, MFR, at 190℃, 2.16 kg, according to ISO 1133 has been defined as specified parameter for quality control. A certificate can be provided with each lot number upon request. In order to obtain a high accuracy for the MFR measurement, the granules should be dried for 5 hours at 80℃.Other data given in our literature are typical values, which are not part of our product specification.

Form Supplied and Storage

Temperatures during transportation and storage should not exceed 70℃ at any time. Storage time is not suggested to be over 12 months under proper conditions in an unopened bag, the product should be used as soon as possible when the package is opened.

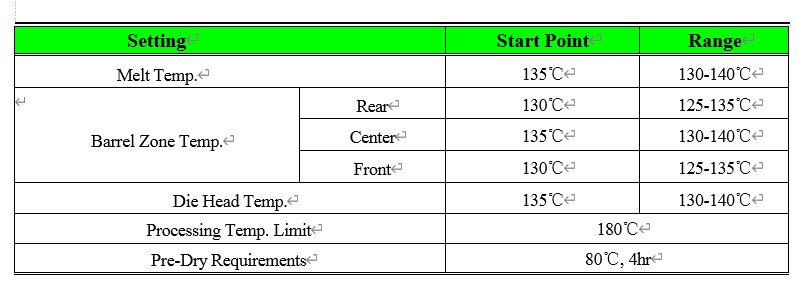

Processing Conditions

Well packaged: products can be used directly. If the package is damaged before use, the product should be dried prior to processing. Moisture levels above 1000 ppm may affect film-blowing operation;Effective drying: takes place at 80°C for 5 hours.

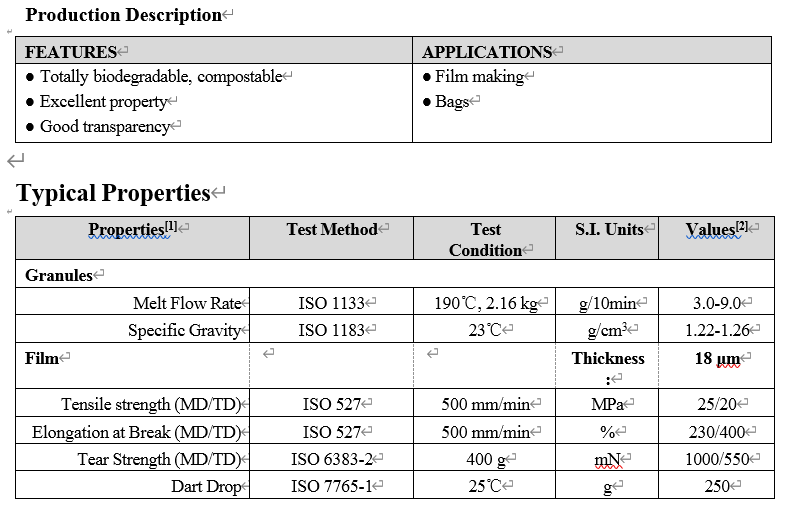

Processing parameters for blowing film:

Safety Advice

Direct contact with the melting resin should be avoided during processing operations. The processing area should be well ventilated, as during processing the materials might emit fumes containing decomposing substances, which may be irritating. We recommends that clients should investigate the application demand of their products in advance to ensure proper use of this product, and feel free to contact with us for technical support when necessary.

5、ECOPOND® Compostable Polyesters D300 M20

Quality Control

The melt flow rate, MFR, at 190℃, 2.16Kg, according to ISO 1133 has been defined as specified parameter for quality control. A certificate can be provided with each lot number upon request. In order to

obtain a high accuracy for the MFR measurement the granules should be dried for 5 hours at 80℃.Other

data given in our literature are typical values, which are not part of our product specification.

Storage

Temperatures during transportation and storage may not exceed 70℃ at any time. Storage time in an unopened bag may not surpass 12 month at room temperature (23℃).

Processing Conditions for Blowing Film

Well packaged products can be used directly. If package is damaged before use, the product should be dried prior to processing. Moisture levels above 600ppm may impair film-blowing operation. Effective drying takes place at 80°C for 4 hours. The dried prod uct should keep away from moisture. The data sheet is just for reference. In actual process, the parameter should be adjusted.